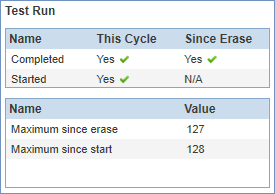

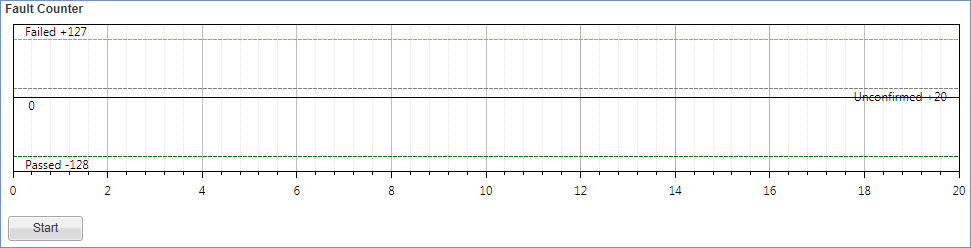

The Fault counter is the most central part of the Graph view and plots the value of the current DTC (captured by the in-vehicle DTC test) in a graph. You can follow the graph to see

if it currently reached maximum values and other limits in order to draw conclusions on the fault's behaviors and degree of

severity. The fault counter steps (or jumps) up each time the test detects a fault. The fault counter steps (or jumps) down

each time the test tries to detect a fault but no fault is detected.

To start monitoring values in the fault counter, click the button. This starts a continuous readout and DTC details are displayed in real time. Click the button again to stop the monitoring.

When the test has started and is running, try to recreate the environmental and operational conditions that were present when

the fault occurred in the vehicle. Also try to reproduce the fault by e.g. jiggling wires to component or by jiggling the

component itself. If you manage to reproduce the fault, the fault counter as mentioned above step (or jump) up to indicate

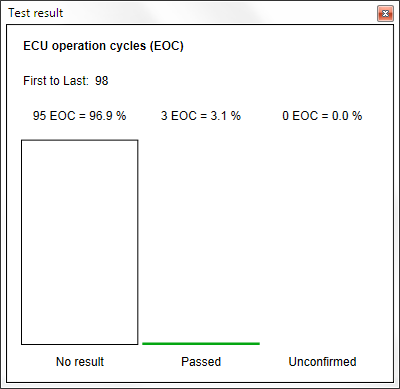

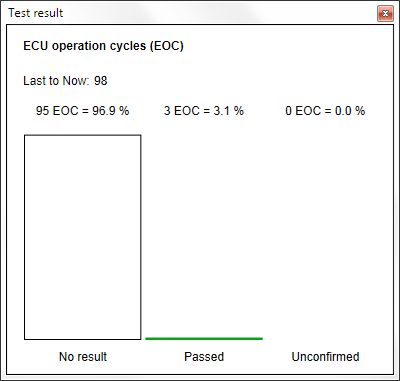

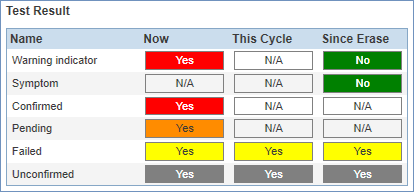

that the fault is active. The test result also shows when a fault limit (Failed and Unconfirmed) is reached.

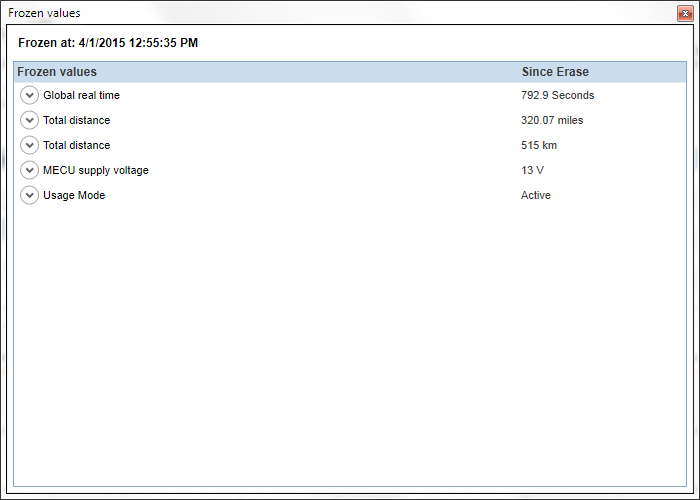

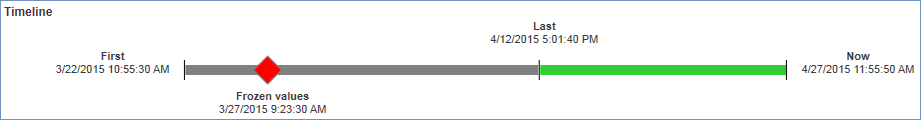

buttons. The frozen values can be used to identify the vehicle's operation condition and environment condition the last time

the fault was detected by the

buttons. The frozen values can be used to identify the vehicle's operation condition and environment condition the last time

the fault was detected by the