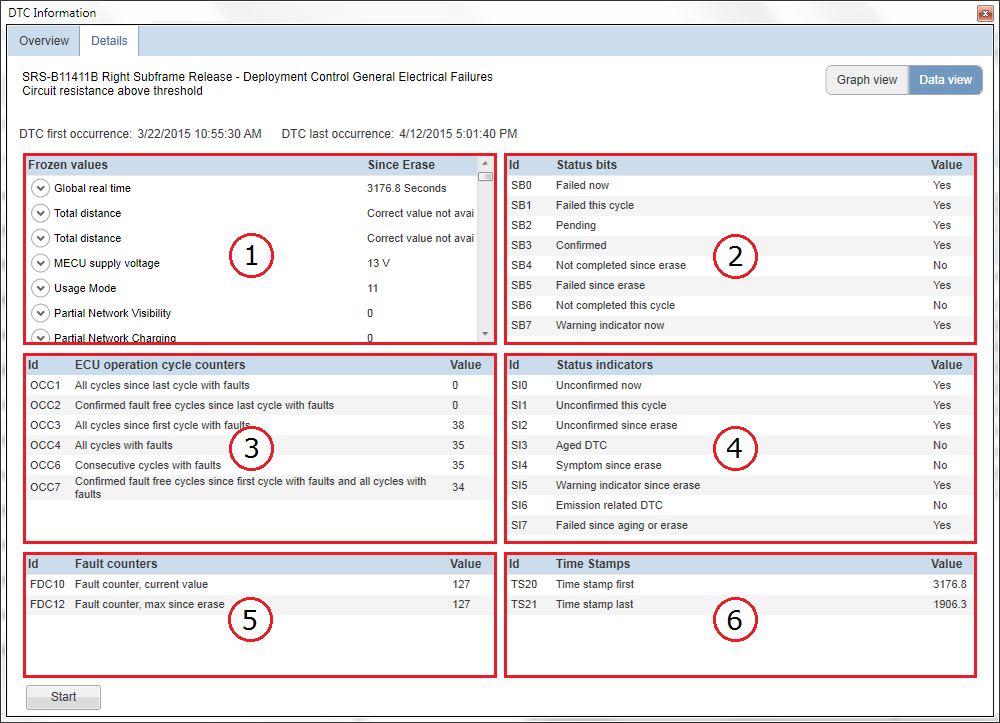

In the Data view you can monitor different kind of statuses and parameters of the control module.

To start monitoring the values in real time, click the button in the lower left part of the window. This starts a continuous readout of DTC details. Click the button again to stop the monitoring.

List descriptions

|

Number |

Name |

Description |

|---|---|---|

|

1 |

Frozen Values |

In this list you can see values of data parameters that have been frozen when a fault was detected by the test. These values can be used to identify the vehicle/ECU operation condition and environment condition in which the fault was detected. |

|

2 |

Status Bits |

In this list you can see the status of the test. You can for instance see if the test has been started and completed, if a fault has been detected by the test and if the DTC has been confirmed. The DTC point out a fault that probably is long duration and lasting if the DTC is confirmed. |

|

3 |

ECU operation cycle counters |

In this list you can see the values of the control module operation cycle counters. The control module operation cycle counters count, for instance, number of cycles in which a fault has been detected and number of cycles since the fault was first and last detected (since erase). |

|

4 |

Status Indicators |

In this list you can see more status of the test. You can for instance see if the DTC has been unconfirmed or aged. The DTC points out a fault that probably is of a short duration and temporary if the DTC is unconfirmed. The DTC may not be relevant anymore if the DTC is aged. |

|

5 |

Fault counters |

In this list you can see the current and maximum value (since erase) of the fault counter. The fault counter step up (or jump up) each time the test detect a fault by the test. The fault counter step down (or jump down) each time the test tries to detect a fault but no fault is detected. So that means, you can see how many times the fault has been detected by the test (now and maximum since erase). |

|

6 |

Time Stamps |

In this list you can see a time stamps that was taken the first and last time the fault was detected. These values can be used to see if the DTC is relevant for the fault that the customer complains about. |